A Complete Guide to Industrial Roller Uses and Benefits

Industrial rollers are essential components in manufacturing and production processes across a variety of industries. From metalworking to packaging, these cylindrical tools play a vital role in ensuring efficiency, precision, and durability. Understanding the different types of industrial rollers, their applications, and the benefits they provide can help businesses optimize operations and improve productivity.

What Are Industrial Rollers?

Industrial rollers are cylindrical devices designed to support, move, shape, or process materials in industrial settings. They can be made from steel, rubber, polyurethane, or a combination of materials, depending on the intended use. Rollers can function as conveyor components, pressing tools, coating devices, or shaping instruments, among other applications.

Types of Industrial Rollers

The variety of industrial rollers available today is extensive. Here are the most common types:

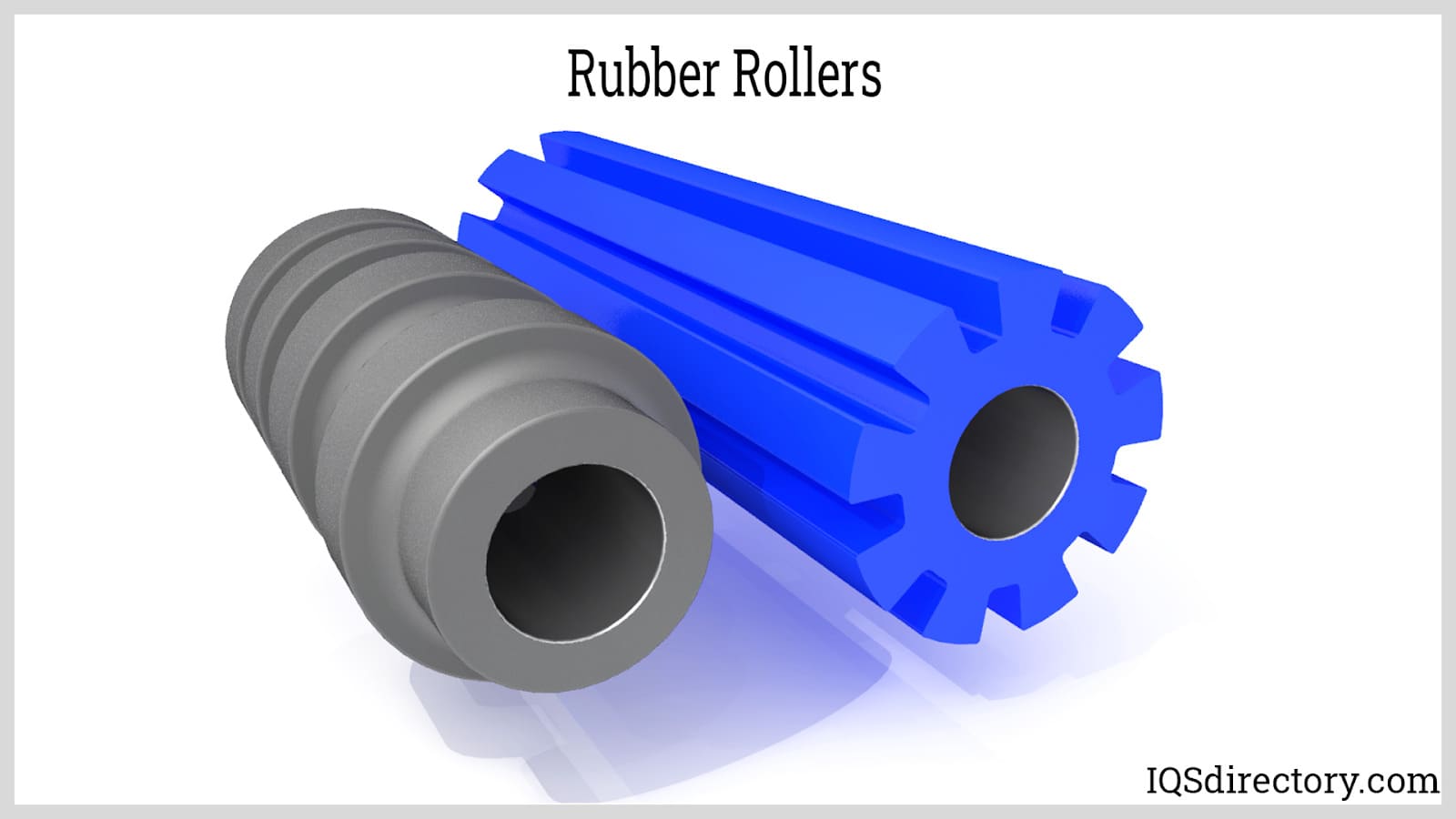

- Rubber Rollers: Often used in printing, laminating, and textile industries, rubber rollers provide grip and cushioning, making them ideal for delicate materials.

- Steel Rollers: Known for their strength and durability, steel rollers are widely used in heavy-duty applications such as metal forming, mining, and paper production.

- Polyurethane Rollers: Combining flexibility and durability, polyurethane rollers resist abrasion and chemicals, making them suitable for specialized industrial environments.

- Driven and Idler Rollers: Driven rollers are powered and control material movement, while idler rollers are passive, supporting the material as it moves along conveyor systems.

- Precision Rollers: Used in machining processes, these rollers ensure accuracy in shaping and finishing metal or plastic parts.

A related component, the lathe steady rest, works alongside rollers in machining operations to support long, rotating workpieces and maintain precision during the turning process. While not technically a roller, it demonstrates the importance of support devices in industrial settings.

Applications of Industrial Rollers

Industrial rollers are versatile and are used in numerous sectors. Some of the key applications include:

1. Conveyor Systems

Rollers form the backbone of conveyor systems in warehouses, factories, and logistics centers. They help move materials efficiently, reduce manual handling, and streamline production lines. Driven rollers control speed, while idler rollers maintain stability and support heavy loads.

2. Printing and Packaging

In printing presses and packaging machines, rollers are critical for transferring ink, laminating materials, or guiding paper and film. Rubber and polyurethane rollers provide consistent pressure, ensuring smooth and precise results without damaging the product.

3. Metalworking

Steel rollers are used in processes like rolling, forming, and shaping metals. These rollers can endure high pressure and repeated stress while ensuring uniformity in thickness and texture. They are also used in sheet metal fabrication to maintain surface quality.

4. Textile Manufacturing

Textile production relies on rollers to stretch, guide, and press fabrics during weaving, dyeing, or finishing. Rubber and polyurethane rollers are ideal here due to their gentle handling and resistance to wear.

5. Food Processing

Food-grade rollers are used in dough preparation, pasta production, and packaging. These rollers must comply with hygiene standards, resist corrosion, and handle high-speed operations without contaminating the product.

6. Material Coating

In industries like paper, textiles, and electronics, coating rollers apply chemicals, adhesives, or paints uniformly across surfaces. The precise design and material of the roller ensure consistent coating thickness and reduce wastage.

Benefits of Industrial Rollers

Investing in the right industrial rollers can yield significant advantages for businesses:

- Enhanced Efficiency: Rollers reduce friction and support smooth material handling, minimizing downtime and increasing throughput.

- Precision and Accuracy: High-quality rollers maintain uniform pressure and alignment, essential in machining, printing, and coating applications.

- Durability and Longevity: Industrial rollers are designed to withstand heavy loads, high speeds, and harsh conditions, ensuring long service life.

- Reduced Labor Costs: Automation with rollers decreases manual handling, improving worker safety and reducing labor expenses.

- Versatility: With various types and materials, rollers can be tailored to suit almost any industrial process.

Choosing the Right Industrial Roller

Selecting the correct roller involves considering factors such as material type, load capacity, speed, and operating environment. Rubber rollers are best for delicate or sticky materials, while steel rollers suit heavy-duty applications. Polyurethane rollers provide a balance between flexibility and durability. Regular maintenance, including cleaning and inspection, ensures rollers continue to perform optimally.

In Conclusion

Industrial rollers are indispensable components in modern manufacturing and production processes. Their applications range from conveyor systems and printing presses to metalworking and food processing, highlighting their versatility and importance. By understanding the types, applications, and benefits of industrial rollers, businesses can make informed decisions that improve productivity, reduce costs, and maintain high-quality output. Incorporating precision tools like the lathe steady rest alongside industrial rollers further enhances accuracy and efficiency, making these tools integral to industrial operations.